Aluminium Die Casting Manufacturer China

Introduction

Welcome to wetronindustrial.com, your one-stop destination for finding a reliable aluminium die casting manufacturer in China. As a leading supplier in the Home & Garden Appliances industry, we are committed to providing high-quality aluminium die castings that meet your specific needs and requirements. In this comprehensive article, we will explore the benefits and the process involved in aluminium die casting to help you make an informed decision.

The Benefits of Aluminium Die Casting

Aluminium die casting offers numerous advantages over other manufacturing processes. Let's dive into some of the key benefits:

Precision and Dimensional Accuracy

One of the major advantages of aluminium die casting is its ability to create complex, intricate shapes with exceptional precision and dimensional accuracy. The die casting process ensures consistent production of parts that meet tight tolerances, ensuring a higher quality end-product.

Lightweight and Strength

Aluminium is renowned for its lightweight properties without compromising on strength. This makes it an ideal material for a wide range of Home & Garden Appliances. Die-cast aluminium components are not only lightweight but also possess excellent mechanical properties, allowing them to withstand demanding environments.

Cost-Effective Production

The aluminium die casting process is known for its cost-effectiveness. With the ability to produce large quantities of parts quickly and efficiently, manufacturers can benefit from economies of scale. This translates to reduced production costs and competitive pricing for the end-users.

High Heat and Electrical Conductivity

Aluminium exhibits excellent heat and electrical conductivity, making it an ideal choice for applications that require efficient heat dissipation or electrical conductivity. Die-cast aluminium components can efficiently transfer heat away from critical areas, ensuring optimal performance and reliability.

Corrosion Resistance

Corrosion can significantly impact the lifespan and performance of components. Fortunately, aluminium has a natural resistance to corrosion, making it suitable for various environments. This makes aluminium die castings a reliable option for Home & Garden Appliances that may be exposed to moisture or other corrosive elements.

The Aluminium Die Casting Process

The aluminium die casting process involves several steps to ensure the production of high-quality components. Here is a brief overview of the process:

1. Tooling Design and Production

The first step in the aluminium die casting process is to design and produce the die casting molds or tools. Skilled engineers use computer-aided design (CAD) software to create detailed tooling designs that match the desired specifications.

2. Molten Aluminium Injection

Once the tooling is ready, molten aluminium is precisely injected into the die casting machine. The high pressure exerted allows the liquid metal to fill the intricate cavities within the mold, ensuring accurate reproduction of the desired shape.

3. Cooling and Solidification

After the molten aluminium fills the mold, it rapidly cools and solidifies. Cooling time can vary depending on the design, complexity, and wall thickness of the component. Proper cooling ensures optimal mechanical properties and dimensional accuracy.

4. Ejection and Finishing

Once the aluminium solidifies, the die casting machine ejects the cooled component from the mold. Minor finishing touches, such as removing excess flash or creating smoother surfaces, may be performed to achieve the desired final appearance and functionality.

Choose Wetron Industrial for Your Aluminium Die Casting Needs

At wetronindustrial.com, we are committed to delivering top-notch aluminium die castings for the Home & Garden Appliances industry. Here are a few reasons why you should choose us as your trusted partner:

- Experience and Expertise: With years of experience, we have honed our expertise in aluminium die casting, ensuring the highest quality products.

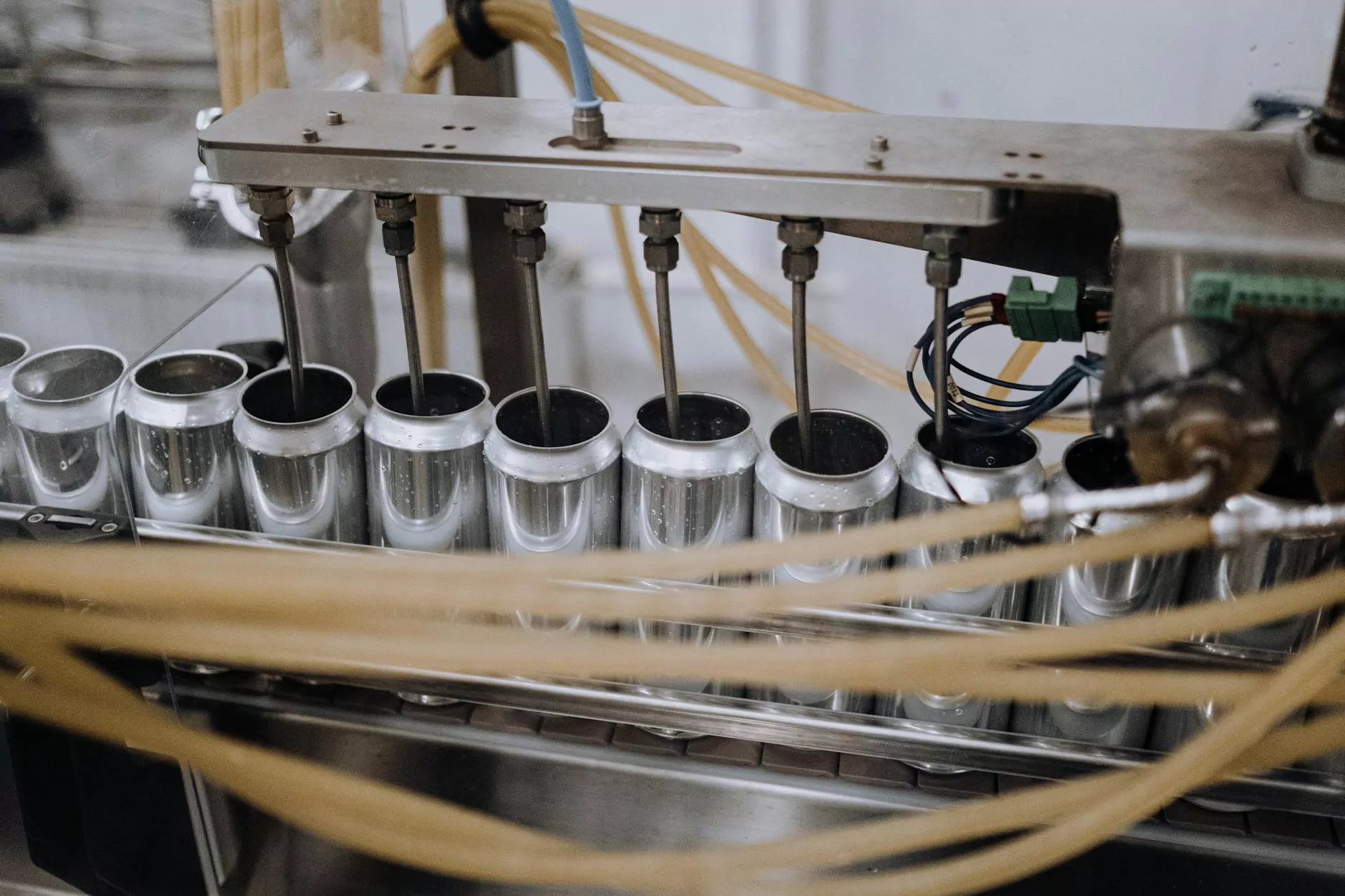

- State-of-the-Art Facilities: Our advanced manufacturing facilities boast cutting-edge technology and equipment, enabling efficient and precise production.

- Strict Quality Control: We have a stringent quality control process in place to ensure that each component meets the highest industry standards.

- Customization: We understand that each project is unique. Therefore, we offer comprehensive customization options to meet your specific requirements.

- Timely Delivery: We are dedicated to delivering your aluminium die castings on time, adhering to agreed-upon schedules and deadlines.

Trust wetronindustrial.com to be your reliable partner in the Home & Garden Appliances industry. Contact us today to discuss your aluminium die casting needs and let us help you turn your ideas into reality!

aluminium die casting manufacturer china